Machines

- Home

- Machines

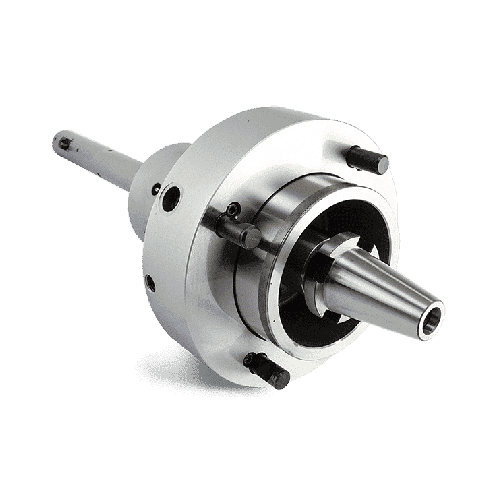

ACE-J400LM

400mm

320mm

200mm

52.5mm

100mm

8 Nos

40mm

25x25mm

ACE-J400LM CNC Machine

Specification

CNC turning centers like the ACE-J400LM are the workhorses of modern manufacturing, specializing in the rapid and highly accurate production of cylindrical components. With a maximum turning diameter of 320mm and a length of 400mm, this machine is perfectly suited for medium-sized parts such as shafts, bushings, flanges, and complex valve components. Its 8-tool turret allows for a complete machining process including turning, facing, boring, and threading to be done in a single setup, minimizing human error and maximizing throughput. The machine’s robust design and 52.5mm spindle bore ensure it can consistently handle a wide range of materials, from soft aluminum to tough stainless steel, making it essential for sectors like automotive, aerospace, and general engineering.

- Maximum Turning Diameter : 320mm

- Maximum Turning Length : 400mm

- Chuck size : 200mm

- Boring bar dia maximum : 40mm

- Bore through spindle : 52.5mm

- Tailstock Quill Travel : 100mm

- Number of Tools Maximum : 8 Nos

- OD Turning Tool size : 25x25mm

Spinner CNC Machine

Specification

Performance, compact machine specifically engineered for the precise and efficient manufacture of small to medium-sized cylindrical components. Built on a rigid Meehanite casting body for superior stability and thermal resistance, it guarantees high accuracy and repeatability in continuous production cycles. This model offers a maximum turning diameter of 250 mm and a spindle speed of up to 3500 rpm, making it highly efficient for achieving fine surface finishes on various materials. Its 32 mm bar capacity and robust design, optionally upgradable with features like a tailstock and bar puller, position the https://www.google.com/search?q=Spinner.com as an economical yet powerful turning solution essential for high-volume precision applications in the Automobile, Aerospace, and General Engineering industries.

- Maximum Turning Diameter : 250mm

- Maximum Turning Length : 325mm

- Chuck size : 165mm

- Number of Tools Maximum : 8 Nos

- Boring bar dia maximum : 40mm

- OD Turning tool size : 25x25mm

LMW Smart Ultra CNC Machine

Specification

The LMW Smart Ultra is a high-precision, two-axis CNC Turning Center manufactured by Lakshmi Machine Works (LMW), designed as part of their Smart Series line for efficient machining of small to medium components. Built with an FG300 grade cast iron body and a slant bed design, the machine ensures superior rigidity, excellent chip management, and high thermal stability, all contributing to its long-lasting repeatability and accuracy.

The Smart Ultra boasts a maximum turning diameter of 290 mm and a turning length of 370 mm, supported by a powerful spindle that reaches 4000 rpm and rapid traverse rates of 30 m/min in both axes to minimize non-cutting time.

- Maximum Turning Diameter : 280mm

- Maximum Turning Length : 400mm

- Chuck size : 165mm

- Boring bar dia maximum : 40mm

- Tailstock Quill Travel : 100mm

- Number of Tools Maximum : 8 Nos

- OD Turning Tool size : 25x25mm

SJE10 LM/XL CNC Machine

Specification

The SJE 10 LM/XL Turning Center is a high-performance, two-axis horizontal CNC lathe from the ACE Designers’ Jobber Evo series, engineered for maximum productivity and flexibility in medium-to-large component manufacturing. This machine is built to handle significant load, offering a 350 mm maximum turning diameter and a substantial turning length of up to 643 mm. A key feature is the choice of guideway technology: the LM (Linear Motion) version prioritizes high-speed rapids and rapid indexing for mass production, while the XL (Hardened & Ground Box) version provides extreme rigidity and vibration damping essential for heavy-duty roughing cuts on tough materials.

- Maximum Turning Diameter : 350mm

- Maximum Turning Length : 643mm

- Chuck size : 63mm

- Tailstock Quill Travel : 100mm

- Number of Tools Maximum : 8 Nos

ACE 850V (vertical machining center) CNC Machine

Specification

- Travel X : 800mm

- Travel Y : 510 mm

- Travel Z : 500 mm

- Table size : 1000x510 mm

- Number of Tools Maximum : 24 nos

Circular Saw Cutting (ITL)

Specification

The ITL PowerCut 500 is a heavy-duty, high-performance Circular Saw Cutting Machine designed and manufactured by Industrial Tools & Logistics (ITL) for precision cutting of ferrous and non-ferrous materials, including steel, aluminum, and various alloys. As the flagship model in ITL’s Pro-Series, it is engineered for fast, burr-free cuts in industrial production environments.

The machine features an oversized, vibration-dampening chassis constructed from high-tensile stress-relieved steel, which houses a precision-machined gear drive system. This robust construction ensures maximum stability, minimal runout, and exceptional longevity even under continuous, high-load operation.

Band Saw (Manual)

Specification

The ITL FabCut H350 is a durable and reliable Horizontal Band Saw Machine designed by Industrial Tools & Logistics (ITL) for general-purpose cutting of solid, tubular, and structural materials in maintenance shops, fabrication plants, and general engineering workshops. This manual-feed model is optimized for straight, high-accuracy cuts with maximum operator control.

The machine features a heavy-gauge fabricated steel base and saw bow that provides exceptional rigidity and reduces vibration, ensuring smooth cutting performance and extending blade life. The cutting action is controlled manually: the operator initiates the cut and uses a hydraulic downfeed control valve to regulate the descent rate of the saw bow, allowing for precision adjustment based on the material’s properties.

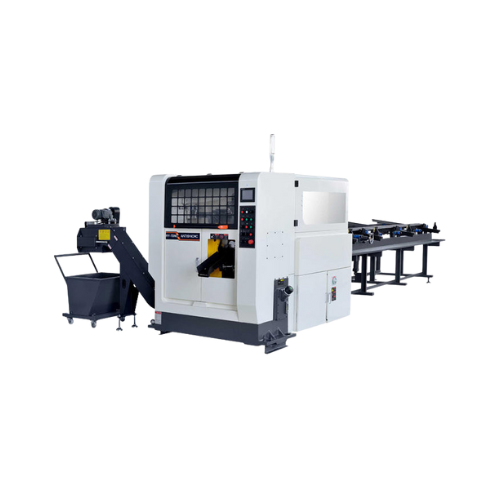

High Speed Circluar Saw Cutting CNC Machine

Specification

The SJE 10 LM/XL Turning Center is a high-performance, two-axis horizontal CNC lathe from the ACE Designers’ Jobber Evo series, engineered for maximum productivity and flexibility in medium-to-large component manufacturing. This machine is built to handle significant load, offering a 350 mm maximum turning diameter and a substantial turning length of up to 643 mm. A key feature is the choice of guideway technology: the LM (Linear Motion) version prioritizes high-speed rapids and rapid indexing for mass production, while the XL (Hardened & Ground Box) version provides extreme rigidity and vibration damping essential for heavy-duty roughing cuts on tough materials.

- Round Bar : 800mm

- RCS Bar : 510mm

- Accuracy of Cutting surface : ± 0.20mm

- Stock Bar Length : 3 – 6 Mtr

| Instrument Name | Range |

|---|---|

| Air Gauge Unit Model A1 | +/- 40μm |

| VernierCaliper digital | 0-300 |

| Micrometer | 0-25mm |

| Micrometer | 25-50mm |

| Micrometer | 50-150mm |

| FLANGE Micrometer | 0-25mm |

| BLADE Micrometer | 25-50mm |

| Bore Dial Gauge | 10-18mm |

| Bore Dial Gauge | 18-35mm |

| Bore Dial Gauge | 35-60mm |

| Bore Dial Gauge | 50-150mm |

| Dial | 0.01mm |

| Dial | 0.001μm |

| Surface Table | 630x630x80mm |

| Hook depth Vernier | 0-150mm |

| Groove Vernier | 22-150mm |

| Micrometer | 150-300mm |