Services

- Home

- Services

Automobile Components

At Ashaapooran High Tech CNC Solutions, we specialize in delivering highly qualified and high-precision components essential for the demanding Automobile sector. Utilizing our advanced VMC and CNC Turning machines, we precisely machine complex parts related to the engine, transmission systems, and chassis. Our core CNC capabilities are dedicated to providing components that require intricate features like sharp threading and superior surface finish. The precision of our ISO-approved parts is crucial for ensuring optimal vehicle performance and long-lasting operational reliability. We adhere to stringent quality control standards, ensuring that only zero-defect parts are delivered to our customers across the industry. Partner with us for customized CNC solutions, whether you are launching new automobile projects or require accurate spares for existing machinery

Pump & Valve Spares

The reliable function of industrial fluid control systems depends entirely on the precision of their internal components. Ashaapooran specializes in manufacturing high-precision spares for both the pump and valve industry, where extremely tight tolerances are non-negotiable for proper sealing and efficient flow regulation. Our advanced CNC machining techniques, including VMC and high-speed CNC Turning, allow us to expertly craft critical components such as shafts, impellers, casings, and specialized seating surfaces. We ensure exceptional dimensional accuracy and superior surface finishes to prevent leakage and optimize the lifespan of the entire system. From intricate flow control mechanisms to larger valve bodies, we provide reliable and ISO-certified custom manufacturing solutions designed to meet the high demands of industrial fluid dynamics applications.

Customized Couplers & Components

Reliable power transmission across machinery depends on perfectly engineered couplers, and we specialize in manufacturing components tailored precisely to your application. We design and machine Customized Couplers to handle specific torque, misalignment, and dimensional requirements that standard parts often fail to meet. Utilizing our advanced CNC Turning and VMC capabilities, we expertly manage complex internal and external geometries and critical keyway slots with extreme accuracy. Whether you require couplers made from specialized metals for high-stress environments or unique designs for vibration damping, our ISO-certified process ensures superior material integrity and precise fit. This dedication to precision guarantees enhanced performance, reduced downtime, and extended machine lifespan. Trust Ashaapooran to deliver bespoke coupling solutions that integrate seamlessly and perform flawlessly in your system.

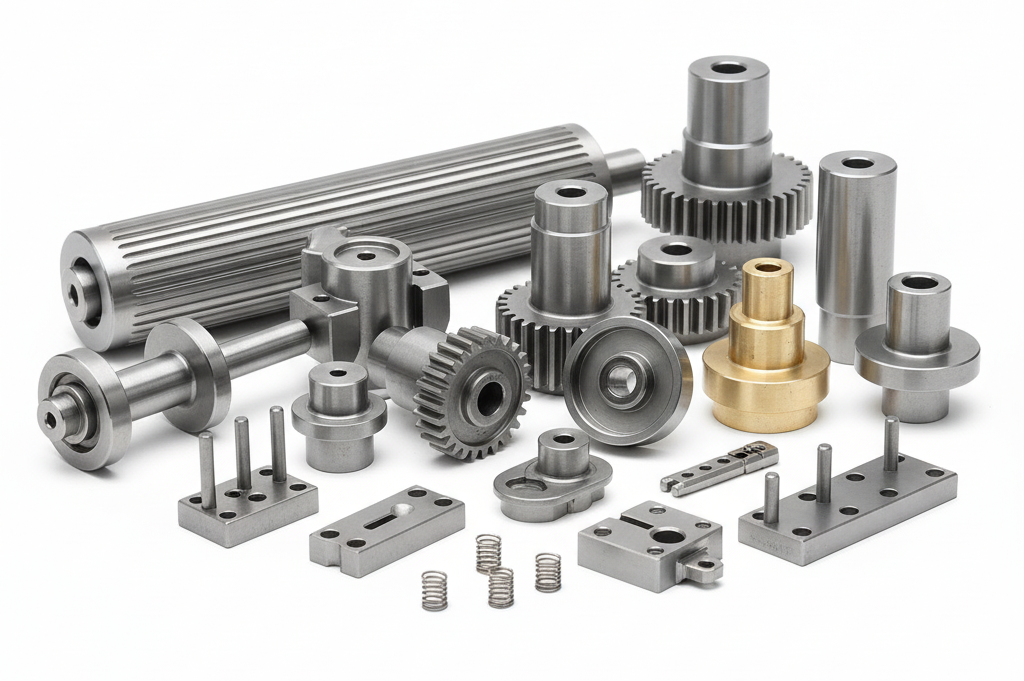

Textile & Automation Spares

The modern Textile and Automation industries rely heavily on continuous, high-speed operations where even minute inaccuracies can lead to costly downtime. Ashaapooran provides specialized, high-precision spares that ensure the smooth and consistent running of automated machinery. Using our advanced VMC and CNC Turning capabilities, we manufacture critical components like precision rollers, specialized spindles, complex gears, and custom jigs and fixtures. We focus on achieving superior surface hardness and minimizing wear and tear, which is essential for components constantly under friction and high load. By delivering parts with unparalleled dimensional repeatability, we help our clients maintain peak production efficiency and minimize material waste. Partner with our ISO-certified facility for reliable component manufacturing designed for the demanding environment of automation and textile applications.

Threading

Threading is a fundamental process for mechanical assembly, ensuring secure fastening and reliable sealing in critical components across all industries. At Ashaapooran, we utilize our state-of-the-art CNC Turning centers to execute highly accurate internal (ID) and external (OD) threading for diverse applications. Our specialized expertise covers a wide range of thread forms, guaranteeing strict adherence to the tightest pitch and tolerance specifications required for critical applications. This precision threading is essential for the superior performance of hydraulic connections, custom couplers, and crucial engine fasteners in the Automobile and Pump & Valve sectors. By maintaining rigorous quality checks throughout the process, we eliminate defects and ensure every thread provides a perfect, reliable fit, thereby enhancing the overall integrity and safety of the final assembly.